|

2013:

January: before the holidays we spotted an advert

for a "Zoufri", an aluminium lifting-keeler for sale in Saint Malo, which

may give us a good excuse for a nice trip. Despite the

attractive price though, some aspects of this boat are not to our liking:

it's a bit too small (under 9 meters), the hull shape is antiquated, with a

very small stern and an external lifting rudder that looks weak.

In the end we decide to not pursue this purchase.

A "Zoufri" similar to the one for sale

January 30th: We go to Aprilia Marittima, few meters

from where we used to keep Shaula3, to see a Bavaria 340 and an Elan 31.

The Bavaria is not bad, although it needs some repairs and the price is

higher than our budget. On the other hand the Elan is in

very poor condition, the first example of many: at the price we have in

mind, boats on offer are either old and poorly maintained, or of

little-known makes or models. We are also surprised to see how

boats claimed to be "ready to sail" are actually very far from being in good

condition!

If we want a more recent boat, or one which has been

already refurbished, we need to increase the budget by at least 45-50%.

February 20th: we saw the ads for two Bavaria 320,

both German-owned and moored in Croatia and for sale at a price which is in

line with our objectives: we get in touch with the Brokers, in view of

organising a visit.

March 15th: we make a quick trip to Fiumicino, near

Rome, to see a french-built aluminium lifting-keel boat: it's a "Légende

10.40" built by the Grardel yard which we never heard of, it's above the 10

meter tax-exemption limit and the price is higher that our objective, but

the kind of boat is exactly what we would like.

First disappointment, the boat is nice and certainly

strong, but very neglected, the deck is in urgent need of a repainting, same

for the interior woodwork, and inside it's utter chaos!

Nice hull, still modern lines

The interior is

chaotic, there's even the outboard clamped to the saloon table (and dripping

fuel on the floor)!

We leave very disappointed, we like the boat but its

status is terrible and it is definitely not worth the asking price, and the

broker tells us that the seller is not willing to negotiate; we make an

offer for little more than half the asking price and leave, knowing we have

very few chances.

March 23-26th: we've never been in Croatia, so the

trip to Zadar and then Sebenik, to visit two different Bavaria 320, is a

good excuse for some tourism.

And what about the boats? Not bad, both of

them, properly maintained although they are beginning to show their age, and

the price is within our limits.

Also the trip has been pleasant, we saw a Country we did

not know at all, and obviously we kept an eye on the "nautical" aspects, in

view of a possible future cruise in the area.

A nice and

well-kept Bavaria

320

On our way back, we stopped at the Scardona falls

Relaxing in front

of the falls...

...and in the roman amphitheater of Pula

April 3rd-4th: we wrap up our conclusions about the boats seen so far

and, despite the obvious maintenance problems, we have to admit that what we

liked most was the Légende 10.40 we saw in Fiumicino. We

get in touch with the broker making a compromise offer, and after a lot of

bargaining we reach an agreement on the price.

We take an appointment for the final negotiation to be

held in Fiumicino in few days' time!

April 9th: it's done, we signed the sale agreement,

we are once again owners of a sailboat!

April 14-26th: we travel to England for the second

Blue Water Rally 2007/09 participants' meeting that this time is held in

Coniston, in the Lake District. We go there by car

because the idea is to take advantage of this voyage for a bit of tourism in

little-known places and we also plan on our way back to stop at some

ship-chandlers in the Southampton/Portsmouth area for shopping.

Of course, bad luck hits us full-face, in the shape of a

red light on the car's dashboard which lighted up just when we are about to

reach our destination! We bring the car to the

nearest service station, just to be told that the particolate filter is

clogged and needs replacing, a 2500 GBP job, and requiring several days

because the part must come from Germany!

We have no other choice than renting a car and, once the

Blue Water Rally celebration is over, move to another hotel while waiting

for the car to get ready: so much for our touring plans, and we say good bye

to a lot of money as well!...

Group photo of the Blue Water Rally 2007/09

participants' reunion

While we are having fun (...) we make sure that the boat's

papers are sent to the agent that will take care of the transfer of

ownership and the flag change, from French to Belgian.

We also arrange for a professional survey, requested by

the insurance.

We are doing things in a rather hurried-up way, but our

main concern is to reduce as much as possible the time we will have to spend

in Fiumicino before moving the boat to Jesolo.

April 26: we arrive home, with the car full of

boaty stuff, just in time to get the quotation from Pantaenius, which is

more-or-less in line with our expectation, so we can proceed quickly.

May 3rd: we move to Fiumicino, again with a

car-load of stuff, ready to begin the work on the boat.

We begin the

works! Cleaning the hull...

...and the interior as well!

May 7th: our initial plan was to put the boat back

by the week's end, which meant first to finish some jobs which require the

boat out of the water, such as:

- install the new log/depth transducer

- repair or replace the dangerously worn stern-gland

- fix the rudder-lifting system, which is not working

- clean the topsides, which are filthy

- clean the hull and re-apply antifouling paint

The two of us, working like two busy ants, may barely do

it, but...

IT'S RAINING!! Hell if it is raining!

And the forecast is no better until next wednesday!....

GRUNT!!!!

May 9th: the list of urgent jobs is getting longer

and longer:

- the stern-gland is a lump of rust

- the hull is still dirty after one week of hard labor

- the oven is broken

- the gas pipes date back to 1992

- there is no VHF

- nor a chartplotter

- log and depth-sounder are good for a museum

- the flares are out of date

- there is no first-aid kit

- the keel-lifting cable is broken and poorly patched-up

- 3 stanchions are bent and to take them out the lifeline must be cut and

replaced

- the clutches on the rooftop are obsolete and dangerous

- most winches do not turn freely and all are badly worn out

- the tiller handle is broken

- the interior was last painted in 1985

- the electrical wiring is scary (too thin wires going everywere, often

festooning around)

...and so on, and on...

But at least it's not raining!...

May 23rd: it took 4 days of hard work, but finally

the first important repair is done! Now the prop-shaft is

equipped with a shining, modern "pack-less stern gland"!

It's been tough, the old stern-gland would not come off,

so we had to saw it off piece by piece. It's going to be

replaced anyway, we thought!....

One day to get rid of the old parts, and we begin chasing

for replacement parts, and there PANIC begins, because our shaft and housing

are of a strange size and we find NOTHING suitable!! (and the

old parts are in little pieces, totally un-usable!!!...)

...enter Ceresoli, a huge and incredibly well-stocked

store in Fiumicino that caters only for professional nautical equipment;

they are very knowledgeable and very kind as well, and spend a lot of time

to find us a solution, but we have to wait for a part to be shipped from

Bologna.

Two days later, we are at Ceresoli once again to collect

our part: they spend a lot of time to explain how to install the whole

stuff, and off we go to work on the boat!

Of course, not all is well, to connect engine and prop-shaft we need bolts

which are 65mm long, no more no less, and of course they do not exist, so

Baby starts her search for a vise that would allow us to cut 8 10mm bolts

down to size, so in the end all is in place!! (thanks to the

vice lent by Hendrick, more about him in a moment...)

Oh, of course in the meantime it rains!!!

Tomorrow sun is expected, the program calls for a splash

of antifouling in view of putting the boat in the water next week.

May 29: yesterday was the day, we put the boat in

the water, after having applied two coats of anti-fouling, of slightly

different colour, because here around it's very hard to find

aluminium-specific antifouling paint in any quantity!

With the boat merrily floating in what should be her

element (if you see the Tiber water you will understand why we say

"should"!!), the first thing is to make sure that water is not entering via

the new transducer or the new stern-gland.

All OK, we are officially afloat: too bad we have been

rafted as the fourth boat out, meaning that to go aboard or get back on land

we have to merrily jump across 3 boats, maybe while carrying a toilet or an

oven, it will be funny...

Being rafted 4th off is not very

convenient, having to work on board!

June 4th: to be fair, the WC we found on the boat

was operational, sort of-

It was an antique though, which required the services of a huge bilge-pump,

prominently installed at the back of the toilet and connected with rather

filthy-looking pipes which were making the long route to the through-hulls,

even partially blocking access to the tiny wet-locker.

Everything off then, and we install a brand new toilet,

similar to the one we had on Shaula3, before meeting a new problem (there

HAD to be a problem, didn't it?):

Question: what diameter should be the fittings at the two

ends of a pipe?

Answer: depends on the pipe's size, but for sure they should be THE SAME

SIZE, no?

Well, no, that would be too easy! The

fitting on the WC is SMALLER than the one on the through-hull, so the pipe

that fits nicely to the WC is far too small to fit on the through-hull

(which is made of plastic, so better not to risk breaking it...)

And of course they are not soft-plastic pipes, they are

super-strong, wire-reinforced ones!!

Tough work on a vice and using an heat-gun to soften the

pipes, but in the end we succeed, the toilet is installed and operational!

Next day, a relaxing job: replacing the oven!

Small work, if not for the fact that we are the fourth boat out and we had

to carry the old oven ashore and then the new one aboard without tripping on

one of the thousand lines on the decks of our neighbours!

Installing the new oven took a full day, because it was

half-centimetre larger than the old one and we also had to replace all the

gas hoses (one was labelled "a remplacer entre le 1989"......).

We also took the large but alien french gas bottles and put two classical

Camping Gaz (hell how expensive they are!!) in their place, then the usual

fight with the pipes and then we can try lighting the oven...just to

discover that gas is not flowing!!!.....

Actually, gas is flowing, but too few: what could the

problem be? Lazy gas??? The metal pipes and taps are

the original ones, maybe there's some dirt somewhere, replacing everything

is feasible but would take a lot of time, dammit!... In

the end we decide we can live with that for a while, we will fix it for good

in Jesolo.

In the meantime we bought new stoppers and winches for the

roof-top, to replace the antiques we have there, and the sailmaker has

visited to try out the frames for the new spray-hood and bimini: guess what?

They do not fit, tomorrow they will have to come again and devise a

modification....

And time is passing...

June 5th: difficult to describe it, imagine the cry

of a door which was not opened for 20 years, and you may get close! SBRAAAAA!

This is the noise made by the huge cockpit locker's cover,

each time we try to open it! The yard had the bad idea of

making the hinges in aluminium, soldered to the door, and time and

electrolysis have done their job and the hinges are stuck solid!

Not only there's a terrible noise that can be heard at the other end of the

yard, but two hinges out of four are already broken, if another one fails

there will be no way to keep the cover in place!!

And then? And then we buy 4 bog-standard

stainless-steel hinges, we cut off the old ones and we make 24 holes for the

6 x 4 screws needed to install the new hinges, then 3 hours lying in strange

positions to put nuts on and tighten them, and the SBRAAA is gone, together

with another day in which we got no closer to the departure day!!!....

And this is the big problem: instead of doing the

minimal-jobs-before-sailing, as we planned, we are continually running to

fix new problems. Nothing catastrophic, but time is passing

by!!!

June 6th: the Tecnomar yard-cum-marina is one of

the many which litter the last stretch of the Tiber river; it is reported

that nearly 3000 boats are moored here!

Just a 40-meter wide stretch of land between the road and

the river border, divided in properties each not much more than 200 meters

long; the ground hosts boats on their cradles, and along the river boats are

moored 4-or 5-deep; a team of Indian (of all places!) boys take care of

moving the boats when one wants to go out, handling with ease rafts of two

or three boats in the river's current.

A very easy-going management, a very relaxed atmosphere,

everybody is friendly and no opportunity for a good chat gets missed.

Enter Hendrick (or Henrik or Henry).

Hendrick is a character on its own: he showed up at Tecnomar in year 2000

with a 16-meter steel boat he built himself in his homeland Poland.

When talking of self-built boats, one often thinks of a rudimentary, poorly

built bucket of a boat: not this one, this was a simple but well-built

offshore boat which could well have been professionally built in a yard!

During the return leg of a transatlantic circuit, sailing from Brasil where

he had been hit by a nasty food poisoning, Hendrick and his wife were

capsized in a storm, suffering serious wounds which were not attended until

they managed to sail into the Azores, 18 days after the crash!

Arriving in Fiumicino after they had recovered from the

wounds, and with further health problems coming up, the two decided to put

the boat for sale and go back to Poland. Eventually, the boat

was purchased by one of the owners of the Tecnomar Yard.

End of a dream?

Maybe not, after all: despite the obvious lack of funds,

Hendrick came back after some time and managed to obtain the permission by

Tecnomar to build a new boat on the premises: he called the new boat "Barca

Piccola" ("Small Boat" in Italian) because it was only 13 meters long!

Hendrick walking

around in the yard

"Barca Piccola" covered by a temporary structure

Years have passed, also because Hendrick's finances are

clearly very limited and he managed to earn a living by doing small jobs in

the yards of the area, but slowly, working in the open and using rudimentary

rigs, the hull of "Barca Piccola" has taken shape!!

Hendrick is now 70, and he cannot work full-time and must

make do with occasional small jobs and rig the boat with whatever he gets or

with discarded equipment from other boats: he says that next year the boat

will be ready to sail towards the Caribbean, but perhaps he does not

believe it himself.

Funny character, Hendrick: he has learned a passable

italian, and is always ready for a chat and a beer: he tells he was a

lawyer, but also a spy, although his remarkable skill with iron works would

rather indicate a long experience in a nautical yard: he built his boat by

eye, without any drawing, just as they did for centuries!...

Will he ever be able to sail away, or old-age and lack of

money will stop him? I like to think that he will be able

to fulfil his dream and spend his last years peacefully at anchor in a

Caribbean cove!

June 9th: slowly, slowly, things are progressing:

- stern-gland and prop-shaft coupling replacement: done

- installation of the new speed/depth transducer: done

- anchor and chain check and length marking: done

- antifouling paint: done (well, two coats of two different colours...)

- toilet and plumbing replacement: done (and it works, too!)

- oven and gas bottle replacement: done (more or less, doesn't work well)

- stanchion and lifeline replacement: done

- coachroof stoppers and winches replacement: done

- restoration of freshwater faucet in the bathroom: on hold, the piping is

missing!

- outboard fuel leak repair: done (by a mechanic)

- sheets and halyards replacement: done, partially (they cost a lot!)

- a billion small jobs, accessory installations, various arrangements:

eternally ongoing job

- installation of new electronics: just started

- engine check, oil and filters replacement: still to be done!

- fuel tank refilling: to be done

- victualling: mostly to be done

LEAVE!!! (still a lot to do before.....but we can see the

end of the tunnel approaching!...)

June 15: as we said before, the area along the two

branches of the Tiber river are completely used-up by moorings and

hard-standing spaces which host a total of more than 3000 boats, most of

them sailboats.

There's everything around here, from full-fledged marinas

to 5-abreast moorings, and also the boats range from very modest ones to

some which are really nice long-distance sailors.

Generally the atmosphere is friendly and relaxed, and

there is not any show of wealth as it is often the case in Marinas more

north, but another aspect that is characteristic of this area is that it is

a true heaven if you need to do any kind of work on the boat.

In the area you can find a lot of shops and workshops

catering for all possible needs: you need chandlery items? There

are at least 3 or 4 shops, and if they do not have what you are looking

after, normally they can order it for you and get it in 2-3 days.

You need stern glands, filters, dedicated marine-grade

batteries? No problem, there's Ceresoli with their huge stock!

Want to replace the standing rigging? There are at least

two different places where they can make the new one for you.

Need repairs to an inboard- or outboard-motor? Mechanics

and spare-part resellers aplenty!

Sailmakers? 2 or 3, famous ones and less so.

Electrical cables and equipment, which are normally very

hard to find? There's Sbrega, who sells everything!

You need something to be fabricated?

There are a couple of old-timer shops, where you can have everything

custom-built! I needed to solder a part of the new oven, and

they even did not want any money for the work!...

Plexiglass? In Rome.

Tools? In Nearby Ostia or in one of the many

shopping centres.

Supermarkets? Several within few

kilometres.

Only problem, you really need a car (rental available

locally).

June 28: there are still a lot of works needed to

bring this boat in line with our wishes, but the first priority was to bring

the boat up to condition for a 1000-mile journey; we thought to spend about

one month for this, but due to bad weather and unexpected problems, we are

still here after two months!

Now it's time to move though, the engine is not leaking

water like the proverbial sieve anymore, the prop-shaft has an hi-tech

stern-glan that does not leak even a single drop, sails have been checked by

the sailmaker, electronics have been brought to the right century, sprayhood

and bimini are new as well as the lazy bag, engine oil and filters have been

replaced, part of the running rigging is new, the new switchboard gives

power to whatever devices are willing to work, the toilet is new as well as

the oven and the gas bottles and hoses, we are in reasonable conditions to

sail away (and with instruments telling us where we are and where we are

heading, as well!),

cooking, sleeping and going to the bathroom are all taken care of: it's time to leave!

The forecast is a bit uncertain, but by tomorrow or

maximum the day after the conditions should be good, perhaps we will leave

for good!...

Follow on this page the

story of the transfer trip from Fiumicino to Jesolo

August/September: back to work, there are a lot of

things to do, and many jobs are inter-related (the position of the batteries

dictates the position of the fridge, but also of the water tanks, and the

gas locker will condition the positioning of the black-waters tank, and so

on...), but gradually ideas are taking shape, and we can start working!

We begin with the electric system and the instrument

panel, which will require building some new furniture.

The new instrument panel under construction

The chart table

before....

and after!

September 13: we place the order with the "i 40 Ruggenti"

shop in Milan for the remaining Raymarine equipment still pending: Radar

antenna, a second chartplotter, wind instruments, AIS receiver, autopilot.

A big expenditure, but we do not feel like giving up on any of these devices

(we hoped to do without the chartplotter in the cockpit, using an iPAD

networked by wi-fi with the chartplotter under-deck, but trials during the

transfer cruise were disappointing).

We also order two new Harken sheet winches: pity, the ones on the boat are

not bad, but they are quite worn-out.

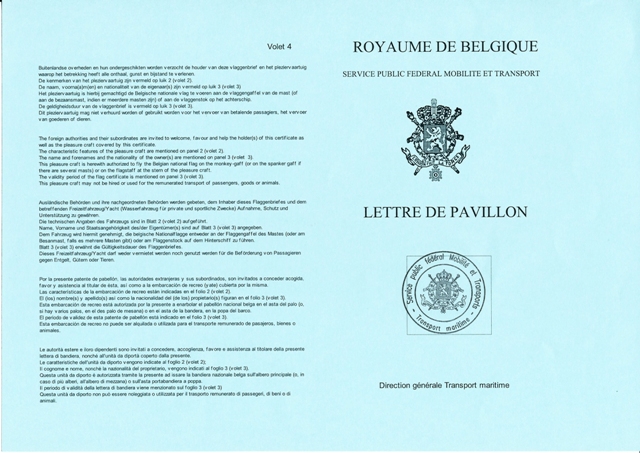

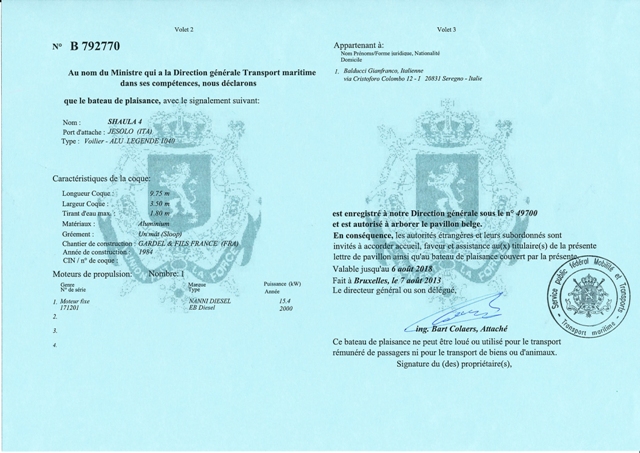

September 16: we finally received the Belgian "Lettre

de Pavillon": now the boat is officially named SHAULA4!!

The "Lettre de

Pavillon Belge" is not very spectacular, just a light-blue sheet of

paper, printed on both sides

September 18th: back in May we ordered some Raymarine equipment to a

British retailer, and everything was delivered in few days except the VHF

radio, which we selected because it featured an integral AIS receiver,

without the need for an external receiver and the obligatory

antenna-splitter. Too good to be true, apparently!

After several months of week-by-week delays, the shop makes the proposal to

deliver, for the same price, just what we did not want, a radio with

separate AIS receiver and splitter! Assuming this means

that the wait could last for a very long time, we give up and in few days we

get the stuff.

October 25th: we got from Belgium also the

Radio-License, now we are ok with all the papers!

Handling paperwork with Belgium is very simple, sometimes even feasible by

e-mail or phone, next time we will do ourselves without recurring to an

(expensive) agent!

November 6th: at the end of the month we will have

to go back home in Milan, so time has come to put the boat on the hard, and

we will take advantage of that to dismast, both to replace the rigging and

to make installing stuff on the mast much easier, and we also take the

engine off for an in-depth overhaul.

Few days working on the boat ashore, and it's time to go.

Anyway, weather has deteriorated, it's often raining and the temperature has

dropped, work is not progressing much!

December 15th: we bought an EPIRB, and then we sent

to Belgium (by e-mail) the form to register the device on the radio-license

and to get the code to be programmed in the EPIRB itself (strange procedure,

most Countries do the reverse and just take note of the code that was

programmed on the device by the manufacturer, based on the boat's MMSI

number).

CONTINUE READING THE LOG-BOOK AT

THIS PAGE

|